VFD Braking Resistors for Overvoltage Protection in High-Inertia Applications

Introduction

VFD braking resistors are essential components for controlling regenerative energy in high-inertia industrial applications. Variable Frequency Drives (VFDs) are widely used to manage motor speed, but when driving high-inertia loads such as induced draft fans, conveyors, or servo-driven equipment, frequent deceleration generates excessive regenerative energy. Without proper dissipation, this energy accumulates in the DC bus, leading to overvoltage trips, component stress, and unexpected downtime.

This article explains why VFD braking resistors are necessary, how regenerative energy is generated, and how aluminum-cased braking resistors help stabilize VFD operation in real industrial environments.

How VFD Braking Resistors Work

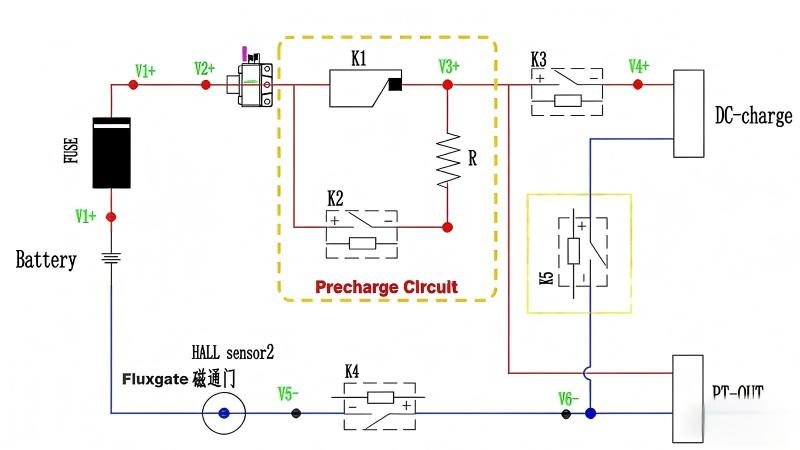

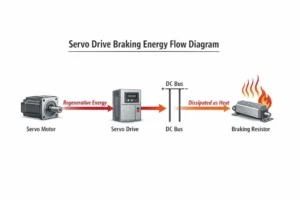

When a motor decelerates while driving a high-inertia load, the mechanical system continues rotating faster than synchronous speed, and the motor acts as a generator. VFD braking resistors provide a controlled path to dissipate this regenerative energy as heat.

The braking unit monitors DC bus voltage:

When voltage exceeds a set threshold, the resistor is switched into the circuit.

Excess energy is safely converted to heat.

Once voltage drops to normal, the resistor disconnects automatically.

Internal braking resistors are suitable for small drives, while external VFD braking resistors are required for high-power or high-inertia applications.

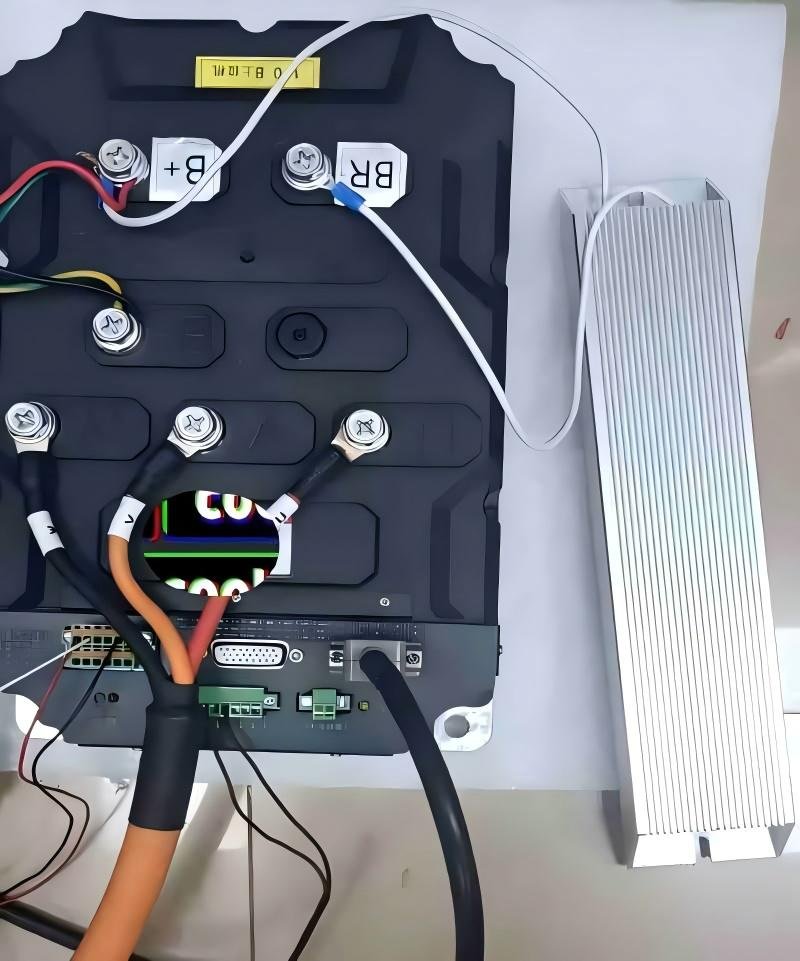

Features of Trapezoidal Aluminum-Cased Braking Resistors

Enhanced Heat Dissipation

The trapezoidal aluminum housing increases surface area compared with rectangular designs, improving airflow. Braided, flame-retardant leads ensure thermal reliability. Heat dissipation efficiency is typically 20–30% higher than standard rectangular aluminum-cased resistors.

High Power Handling Capability

High-performance alloy resistance wire and optimized packaging enable reliable handling of short-term high current surges, common during rapid braking.

Mechanical Strength and Vibration Resistance

Manufactured from high-strength aluminum alloy, the trapezoidal casing resists vibration and mechanical impacts, maintaining performance in industrial environments.

Flexible Installation Options

Trapezoidal structure allows angled or stacked mounting, saving space in compact control cabinets.

Real-World Application Example

At a coal chemical plant, two 18.5 kW induced draft fans experienced frequent VFD overvoltage trips. Installing external aluminum-cased VFD braking resistors dissipated regenerative energy effectively, eliminating nuisance trips and restoring stable operation.

Key Considerations for Selecting VFD Braking Resistors

Load inertia – High-inertia loads usually require external resistors

Resistance value – Must match braking unit specifications

Power and duty cycle – Ensure thermal capacity exceeds braking cycles

Installation environment – Consider airflow, vibration, and enclosure constraints

For guidance on regulatory compliance, see the EU RoHS Directive.

Conclusion

Properly selected VFD braking resistors protect high-inertia drives from overvoltage, ensuring operational stability and extending motor and drive life. Industrial fans, conveyors, and servo-driven machinery benefit from aluminum-cased resistors for safe and reliable regenerative energy dissipation.