How Incorrect Aluminum Braking Resistor Selection Affects Servo Drive Stability?

Common Braking Resistor Selection Mistakes That Affect Servo Drive Stability

Servo Instability Is Often a Braking Resistor Issue

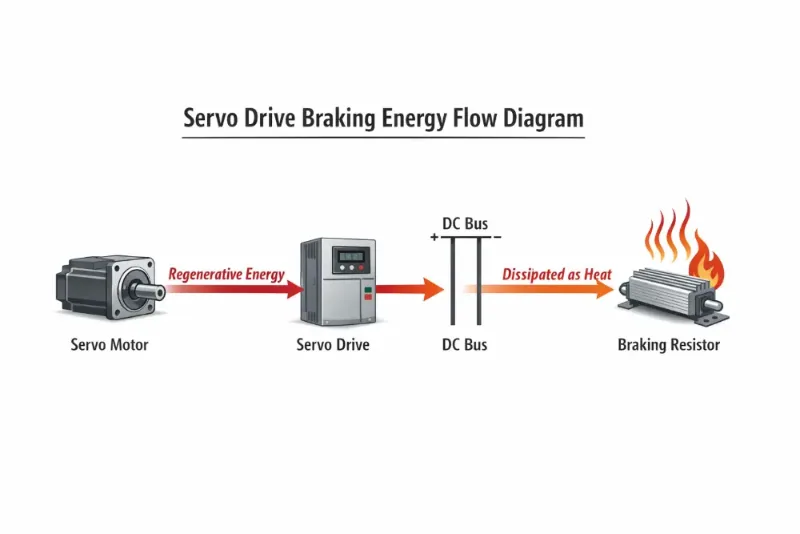

In servo drive systems with frequent acceleration and deceleration, braking resistors play a critical role in dissipating regenerative energy.

In practice, servo drive instability is often caused by incorrect Servo aluminum braking resistor selection, rather than drive or control issues.

Why Aluminum Braking Resistors Matter in Servo Drives

During deceleration, servo motors feed energy back into the DC bus.

If this energy is not dissipated efficiently, DC bus voltage rises and affects system stability.

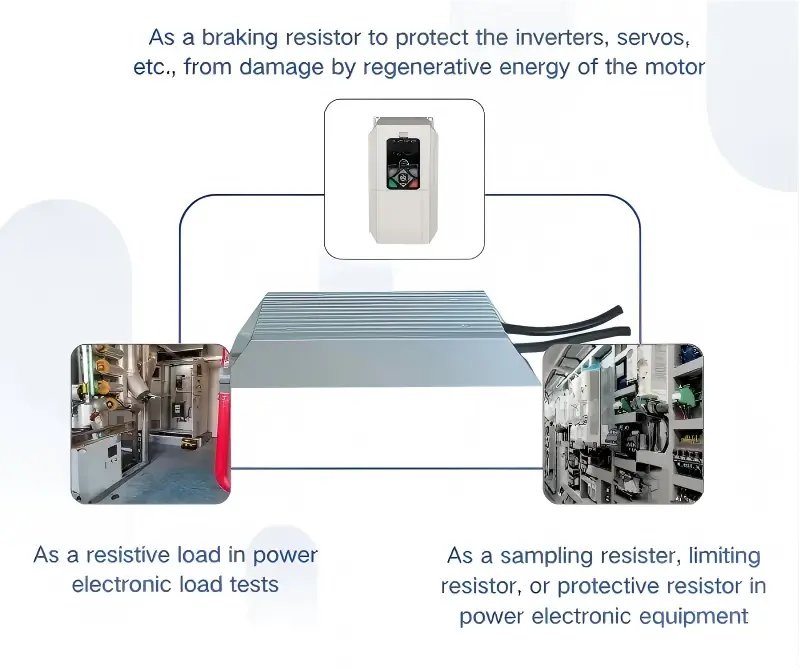

Aluminum braking resistors are designed for high pulse energy, repetitive braking cycles, and effective heat dissipation through mounting surfaces—making them suitable for industrial servo applications.

How Incorrect Selection Affects Stability

Improper braking resistor selection commonly leads to:

DC bus overvoltage alarms

Unexpected servo trips

Inconsistent braking torque

Excessive thermal stress

These issues are frequently misinterpreted as drive-related problems.

Common Braking Resistor Selection Mistakes

1. Selecting Based on Nominal Power Only

Braking is a dynamic process. Ignoring duty cycle and peak energy often results in thermal overload.

2. Ignoring Peak Energy and Braking Frequency

Repeated high-energy braking pulses require sufficient peak energy handling capability.

3. Underestimating Heat Dissipation Conditions

Poor airflow or enclosed mounting reduces actual braking resistor performance.

4. Using General-Purpose Resistors

Non-braking resistors lack the thermal stability required for regenerative energy dissipation.

5. Insufficient Safety Margin

Real operating conditions demand conservative design margins.

From Resistor Selection to Servo Stability

Incorrect selection often follows this chain:

Insufficient braking capacity → Temperature rise → Resistance drift → Unstable energy dissipation → Servo instability

Best Practices for Stable Servo Operation

To ensure servo drive stability, braking resistor selection should consider:

Braking energy per cycle

Braking frequency

Ambient temperature

Mounting and heat dissipation

Correct aluminum braking resistor selection improves stability and long-term reliability.

Aluminum braking resistors used in industrial servo systems are typically manufactured using RoHS-compliant materials to meet global environmental and regulatory requirements.

Compliance with the EU RoHS Directive ensures restricted hazardous substances are controlled in electronic components used in industrial equipment.