Shunt Resistor Based Current Sensing: Circuit Design, Error Analysis, and Practical Selection Tips

Introduction

Accurate current measurement is a fundamental requirement in modern power electronics systems, including motor drives, power supplies, battery management systems, inverters, and industrial automation equipment.

Since microcontrollers and digital processors cannot directly process current signals, the current must first be converted into a proportional voltage signal and then sampled by an analog-to-digital converter (ADC). Among various current sensing technologies, shunt resistor–based current sensing remains one of the most widely used methods due to its low cost, high accuracy, and wide current measurement range.

This guide focuses on practical engineering considerations, including working principles, circuit configurations, error sources, layout techniques, and thermal design trade-offs commonly encountered in industrial shunt-based current sensing applications.

1. Principle of Shunt Resistor Current Sensing

The basic principle of shunt resistor current sensing is based on Ohm’s law:

V = I × R

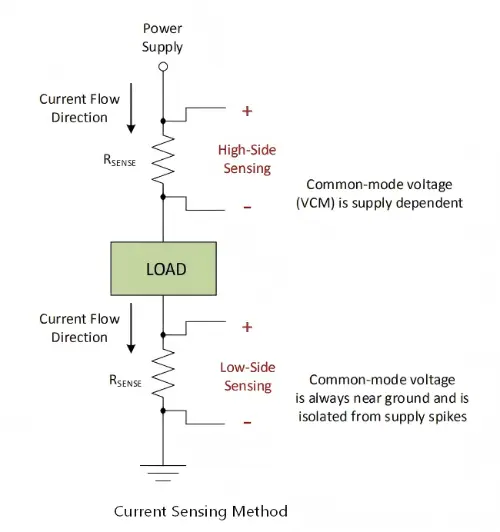

By inserting a low-value resistor into the current path, the flowing current generates a small voltage drop across the resistor. This voltage is proportional to the current and can be amplified using an operational amplifier or a dedicated current-sense amplifier before being processed by the ADC.

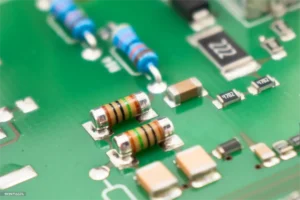

Shunt resistors are typically low-ohmic components, ranging from several milliohms down to micro-ohms, in order to minimize power loss while maintaining sufficient measurement resolution.

Advantages and Limitations

Advantages

Low cost and simple implementation

High measurement accuracy

Suitable for both DC and AC current measurement

Wide measurable current range

Limitations

Introducing a shunt resistor into the current path causes additional power dissipation according to:

P = I² × R

As current increases, power loss and self-heating become significant, making shunt-based sensing less suitable for very high-current applications without proper thermal design.

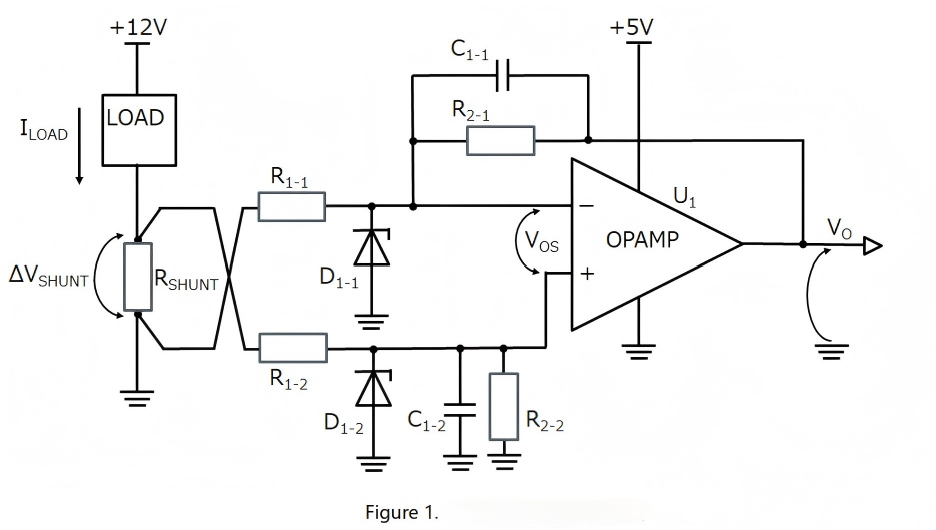

2. Typical Circuit Configurations

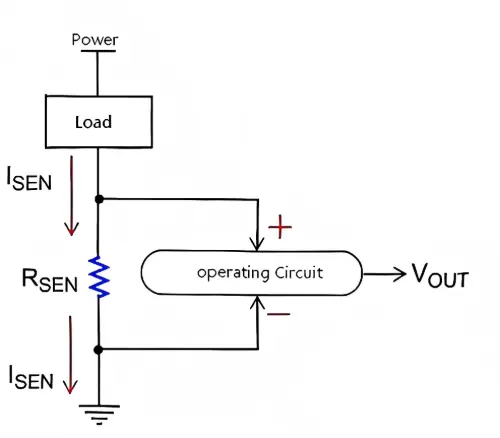

Depending on the placement of the shunt resistor in the circuit, current sensing can be classified into low-side sensing and high-side sensing.

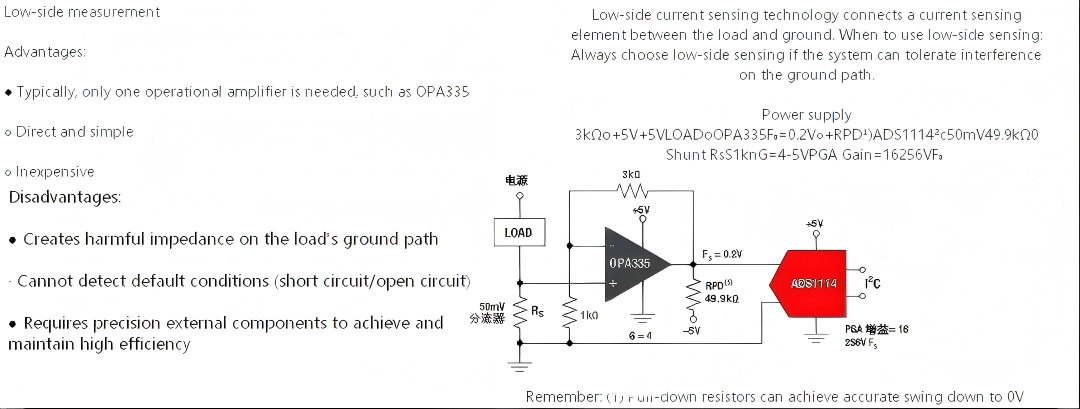

2.1 Low-Side Current Sensing

In low-side sensing, the shunt resistor is placed between the load and system ground.

Low-side sensing is preferred when cost and simplicity are critical and when ground disturbance is acceptable.

Advantages

Low common-mode voltage

Simple amplifier requirements

Easy circuit implementation

Disadvantages

Ground potential shift

Inability to detect load short-to-ground faults

Possible interference with system ground reference

This method is commonly used in industrial and telecom systems with stable ground references.

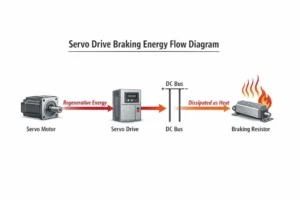

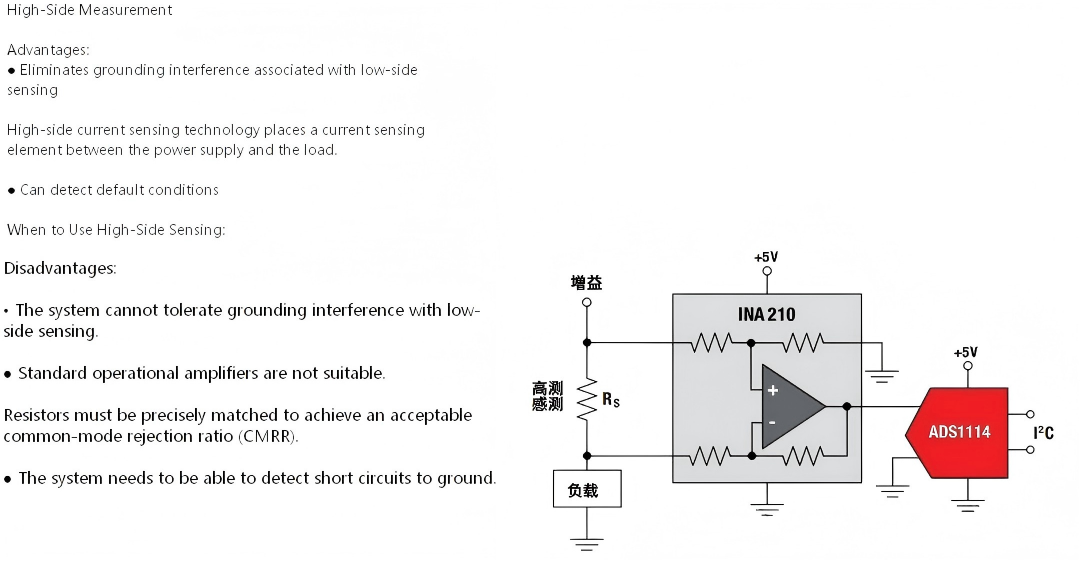

2.2 High-Side Current Sensing

In high-side sensing, the shunt resistor is placed between the power supply and the load.

High-side sensing is commonly selected in safety-critical or fault-detection applications despite higher circuit complexity.

Advantages

No disturbance to system ground

Ability to detect load short circuits

More accurate load current monitoring

Disadvantages

High common-mode voltage

Requires specialized current-sense amplifiers or isolation

Increased circuit complexity

For high-voltage systems, isolated current sensing amplifiers are often required to tolerate large common-mode voltage variations.

For high-voltage systems, isolated current sensing amplifiers are often required to withstand large common-mode voltage variations.

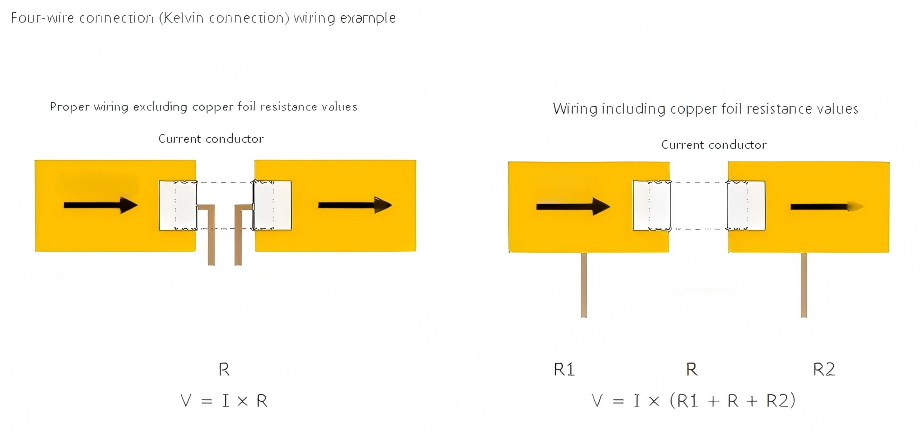

3. PCB Layout and Kelvin Connection

PCB layout is often the largest hidden error source in low-ohmic current sensing.

PCB trace resistance, solder joints, and copper temperature gradients can introduce significant errors, especially when measuring milliohm or sub-milliohm resistance values.

Two-terminal connection includes both solder and PCB trace resistance in the measurement loop

Four-terminal (Kelvin) connection separates current-carrying paths from voltage-sensing paths

Kelvin connection is strongly recommended for high-accuracy current sensing.

Without Kelvin connection, achieving sub-milliohm measurement accuracy is practically impossible.

4. Major Error Sources in Shunt-Based Current Sensing

In practical designs, measurement accuracy is influenced by multiple error sources. Understanding and controlling these factors is essential for achieving stable and reliable current measurement in industrial systems.

4.1 Shunt Resistor Tolerance

The initial resistance tolerance directly defines the baseline measurement accuracy.

Typical tolerance classes include ±1%, ±0.5%, and ±0.1%.

For precision current sensing applications, shunt resistors with tighter tolerance are strongly recommended.

4.2 Temperature Coefficient of Resistance (TCR)

The resistance value varies with temperature according to the temperature coefficient of resistance (TCR), which can introduce measurement drift under operating conditions.

Primary contributors include:

Self-heating caused by I²R power dissipation

Ambient temperature variation

Thermal gradient across the resistor body

Low-TCR alloy materials combined with proper thermal design are essential to minimize temperature-induced error.

4.3 Amplifier Offset and Gain Error

Offset voltage, input bias current, and gain error of the amplifier directly affect output accuracy. These errors become increasingly significant when the shunt voltage is very small.

Careful amplifier selection and proper calibration are required for high-precision measurements.

4.4 Power Dissipation and Thermal Gradient

High current results in significant power dissipation:

P = I² × R

Uneven temperature distribution across the resistor may generate thermal electromotive force (EMF) and additional offset errors, further degrading measurement accuracy.

For a general definition of current shunt measurement, see:

Current sensing – Wikipedia

https://en.wikipedia.org/wiki/Current_sensing

5. How to Select a Shunt Resistor for Your Application

Proper shunt resistor selection is the most critical step in current sensing design.

5.1 Resistance Value Selection

The resistance value should balance:

Sufficient output voltage for ADC resolution

Acceptable power loss

Minimal impact on system efficiency

Typical full-scale shunt voltage ranges from 50 mV to 100 mV.

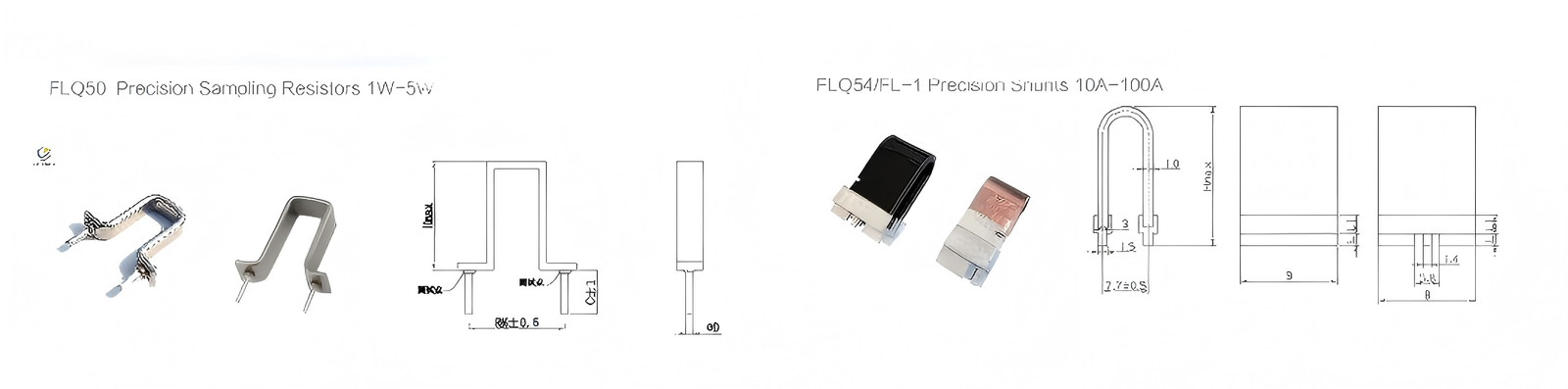

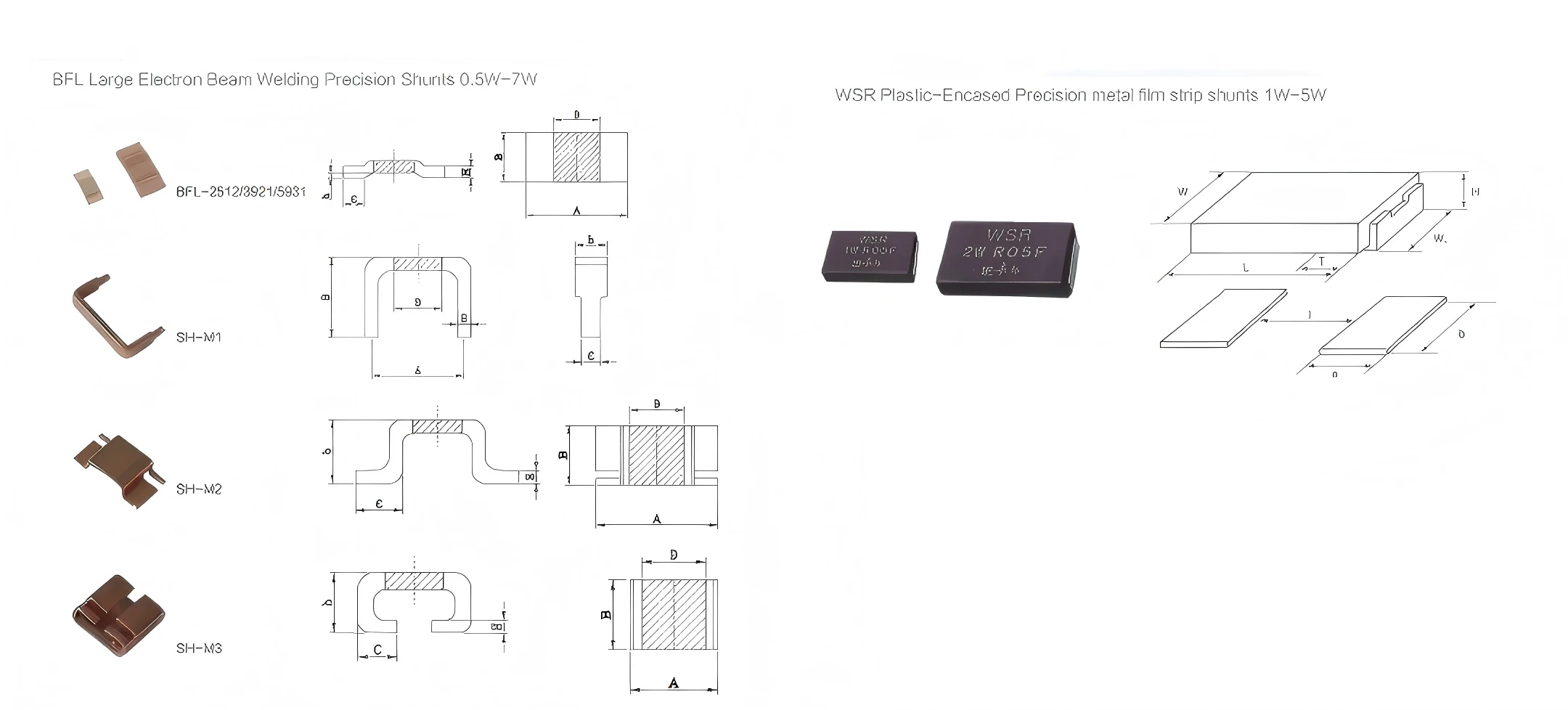

For high-current and precision applications, metal element and metal strip shunt resistors are commonly used due to their low inductance, high power capability, and long-term stability.

5.2 Power Rating and Derating

Designers should always consider:

Continuous current rating

Short-term overload capability

Adequate derating margin

In industrial designs, a derating factor of approximately 50% is commonly applied.

5.3 Accuracy and Long-Term Stability

Key performance indicators include:

Initial tolerance

Load life drift

Thermal stability

Resistance aging behavior

In precision systems, long-term stability is often more critical than initial tolerance.

5.4 Package and Construction

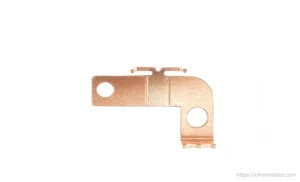

Different constructions provide different performance characteristics:

Metal strip shunt resistors

Metal element open-air shunt resistors

Four-terminal Kelvin shunt resistors

Metal strip and metal element constructions offer:

Low inductance

High pulse capability

Excellent thermal performance

These types are widely used in power conversion, motor drive, and inverter systems.

5.5 Environmental Considerations

Designers should evaluate:

Vibration and mechanical stress

Humidity and corrosion

Industrial temperature range

Cooling and airflow conditions

Proper packaging and surface treatment significantly improve long-term reliability.

6. Practical Design Example

Consider a current measurement system with the following requirements:

RMS current: 21 A

Peak current: 30 A

ADC reference voltage: 3 V

Target accuracy: 1%

Assuming a shunt voltage of 150 mV at peak current:

R = 0.15 V / 30 A = 5 mΩ

Power dissipation at RMS current:

P = 21² × 0.005 = 2.205 W

With a derating factor of 2, a 5 W rated shunt resistor is recommended.

This example highlights the importance of evaluating both electrical and thermal limits during shunt resistor selection.

7. Common Design Mistakes and Practical Tips

Common mistakes

Ignoring PCB trace resistance

Not using Kelvin connection

Underestimating self-heating effects

Selecting insufficient power margin

Poor thermal layout

Practical tips

Use four-terminal shunt resistors whenever possible

Place sense traces close to resistor terminals

Provide sufficient copper area for heat dissipation

Keep sense lines away from high-noise switching paths

Conclusion

Shunt resistor–based current sensing remains one of the most cost-effective and accurate solutions for industrial current measurement.

By carefully considering resistance value, power rating, temperature coefficient, layout technique, and long-term stability, designers can achieve highly reliable and accurate current sensing performance.

For high-current and precision applications, selecting the appropriate shunt resistor construction and material is critical to ensuring long-term system reliability.