Description

Overview

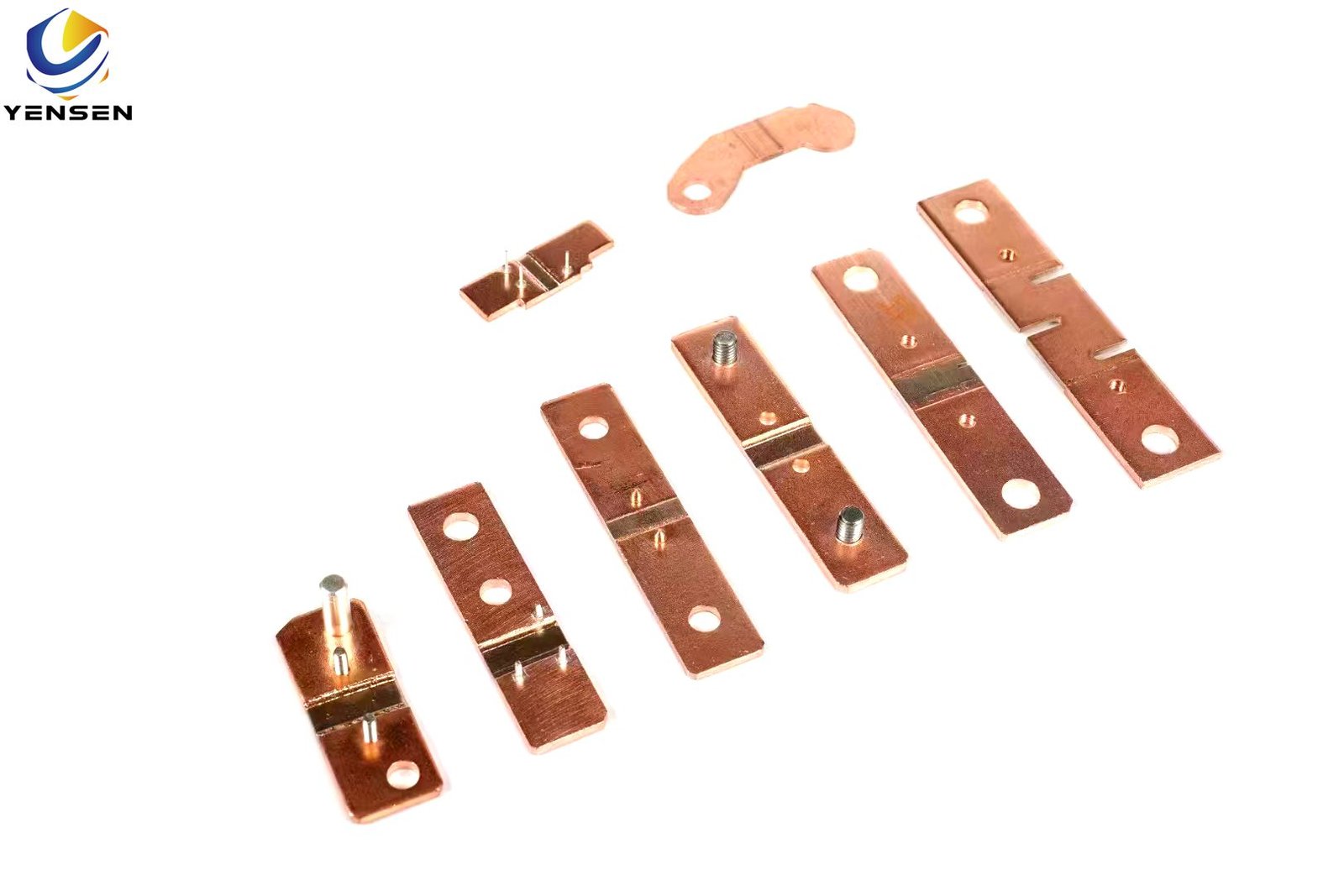

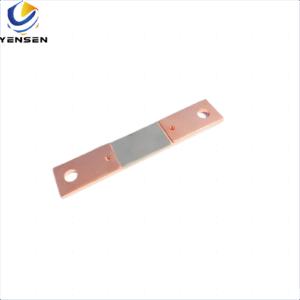

Our high-precision battery shunt resistors are designed for demanding applications in electric vehicles (EV), energy storage systems (ESS), and lithium-ion battery management systems (BMS). Manufactured with electron beam welding (EB welding) technology, they offer superior accuracy, thermal stability, and long-term reliability under harsh operating conditions.

Key Features of Our Electron Beam Welded Shunt Resistor

🔹 Rated Current: 50A to 1000A (customized available)

🔹 Accuracy: ±0.1% to ±1.0%, suitable for precision monitoring

🔹 Low TCR: Ensures stability across temperature variations

🔹 EB Welding: Strong, consistent joints with low resistance

🔹 Compact Size: Space-saving design for modern battery packs

🔹 Custom Solutions: Logo, resistance value, and mounting holes customizable

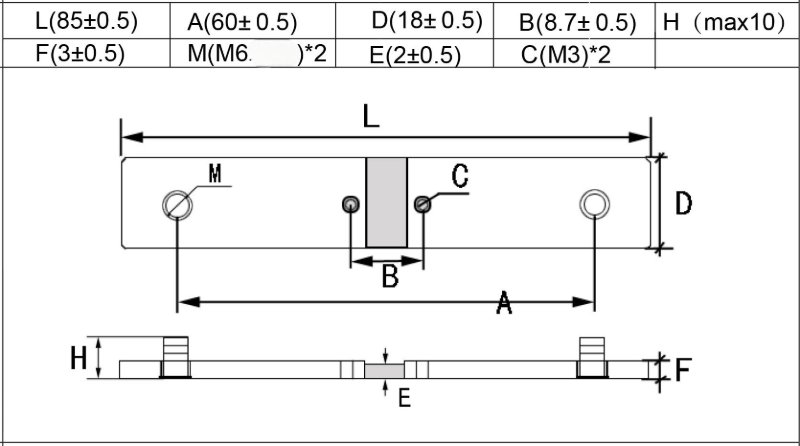

Dimension

Technical Parameters

| Parameter | Specification |

|---|---|

| Rated Current | 400A |

| Resistance | 50μΩ |

| Accuracy Class | Consistency ±1% |

| T.C.R (ppm/℃) | ≤50 |

| Manganese Copper Material | GB 6J12 Precision Manganese Copper |

| Copper Material | National Standard T2Y2 |

| Operating Temperature Range | -50℃ ~ +170℃ |

Applications in Southeast Asia

🔋 EV Battery Pack Monitoring – For e-motorcycles, tuk-tuks, and light electric vehicles in Thailand, Vietnam, and Indonesia

⚡ Home & Commercial Energy Storage Systems – Reliable current detection in solar ESS units

🏭 Battery Management Systems (BMS) – Integrates with current sensors and safety circuits

🧰 UPS and Backup Power Solutions – Stable operation under fluctuating loads in industrial systems

- To explore detailed specifications and best practices for current sensing in electric vehicles,

visit the IEEE official site.

Looking for a Reliable Battery Shunt Resistor Supplier?

Let’s start with samples and drawings! Contact us to get a quick quote and join our growing client base in Southeast Asia.

Learn more about our battery shsunt solutions →Manganin Precision Current Shunt Resistor