Current Sensing Busbar with Shunt for Industrial Drives

Integrated shunt for accurate current sensing

High-conductivity copper body

Compact and space-saving design

Ideal for industrial motor drives and inverters

Customizable specs and RoHS compliant

Description

Overview

This integrated copper busbar with shunt is designed for precision current measurement in high-power industrial drive systems. It combines efficient power distribution with accurate current sensing by embedding a manganin or low-resistance shunt directly into the copper busbar. This compact, dual-function design simplifies system wiring, enhances safety, and improves space utilization.

🔧 Key Features of Current Sensing Busbar:

Integrated current sensing – Built-in precision shunt for real-time current monitoring

High conductivity – Oxygen-free copper ensures low resistance and minimal energy loss

Compact design – Saves space and reduces wiring complexity in control cabinets

Reliable performance – Handles high loads with excellent thermal and mechanical stability

Customizable specs – Resistance values, terminal shapes, hole positions can be tailored

📌 Applications of Current Sensing Busbar:

Frequency inverters and motor control systems

Industrial automation and machinery

Power modules and servo drives

Battery monitoring in power supply units

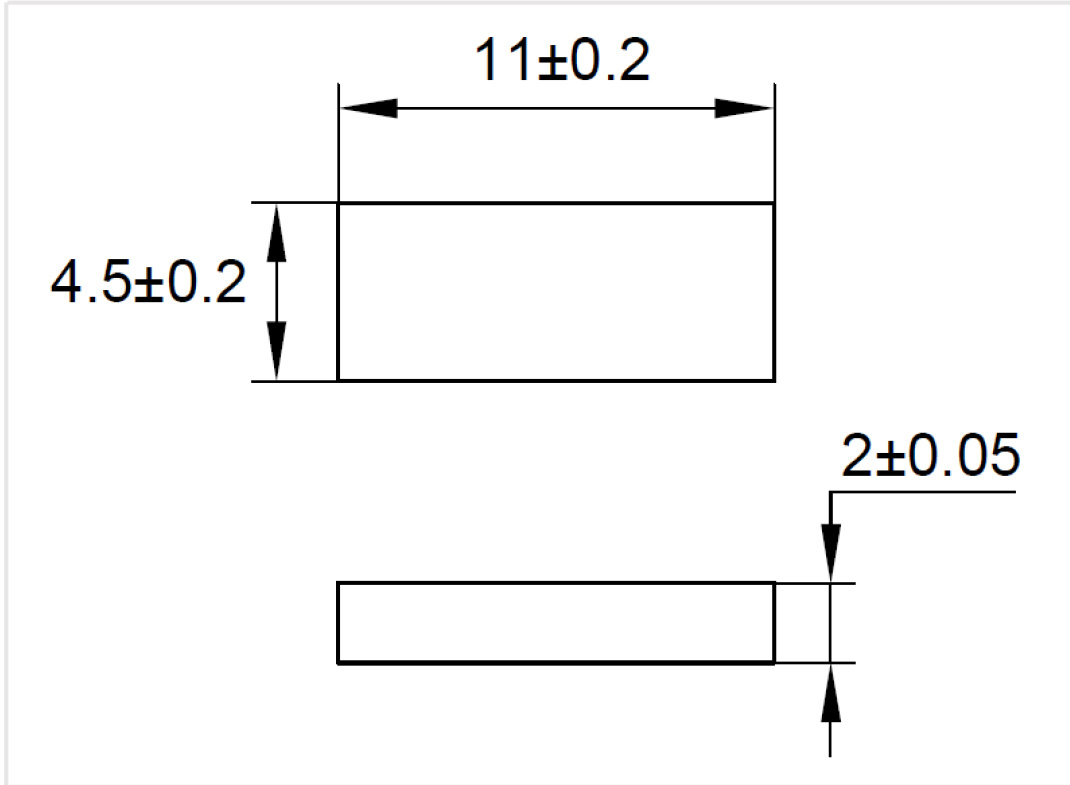

| Type | T | 2 | 4.5 | 11 | I |

| YST | Patch | thickness | width | length | Shape Line |

⚙️ Specifications:

Material: T2 Copper + Manganin Shunt

Rated current: Up to 500A (customizable)

Resistance tolerance: ±1%~±5%

Surface: Bare / Tin-plated / Insulated

RoHS compliant, available with 2D/3D drawings upon request