How to Choose the Right Shunt Resistor for Your VFD Drive?

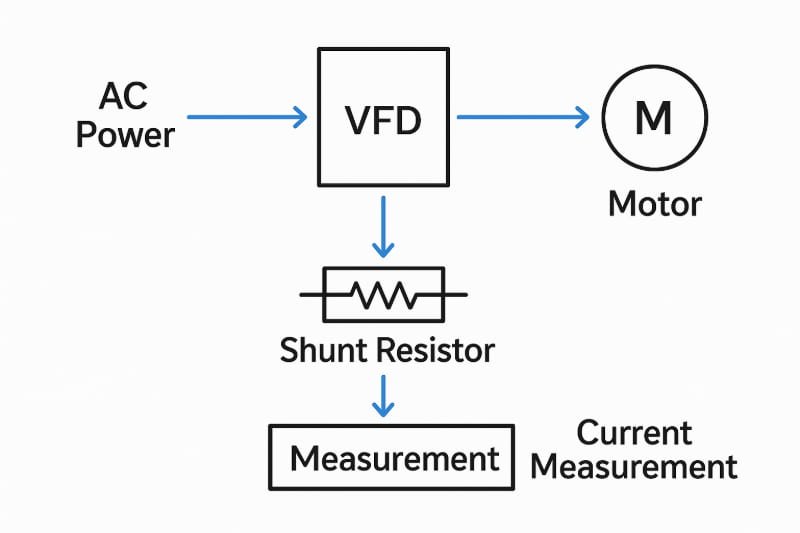

Understanding the Role of Shunt Resistors in VFD Systems

Variable Frequency Drives (VFDs) are essential for controlling motor speed and torque. To ensure reliable braking and overload protection, engineers often integrate a shunt resistor — also known as a current sense resistor — into the system. A well-matched VFD braking current shunt enables precise measurement of braking current and helps regulate energy dissipation.

Why VFD Systems Require Braking Current Shunts

- Accurate Current Monitoring: Measure motor current during braking or regenerative cycles.

- Overload Protection: Detect overcurrent conditions and avoid damage to sensitive components.

- Energy Dissipation: Absorb and convert excess electrical energy into heat using braking resistors.

Key Factors When Choosing a Shunt Resistor for Your VFD

- Rated Power and Pulse Load:

Ensure the resistor can handle repetitive braking energy without failure. Look for aluminum-housed or wirewound resistors for high wattage. - Resistance Value (Ω):

A lower resistance offers minimal voltage drop but must still provide detectable signals to the controller. - Tolerance and TCR:

Select a current sense resistor with tight tolerance (±1% or better) and low TCR for stable readings. - Mounting Type:

Choose between through-hole, SMD, or panel-mount depending on your VFD design.

Recommended Types of Shunt Resistors for VFD Drives

Here are some popular options that fit industrial-grade VFD systems:

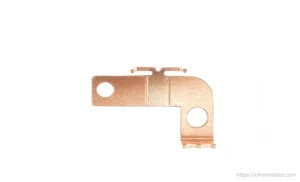

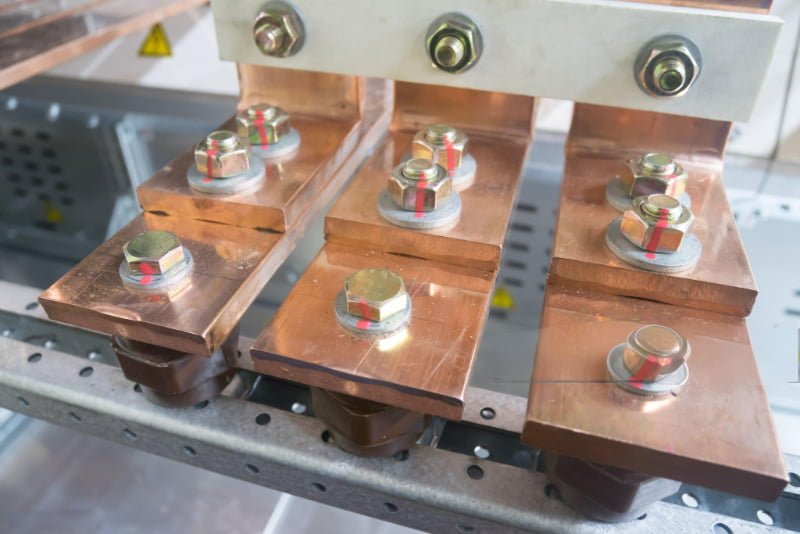

- EB-welded metal strip shunts: High-current, low-resistance, low-inductance.

- Aluminum-housed brake resistors: Excellent for servo motor drives and heavy-duty VFDs.

- Precision current sense resistors: For control circuit feedback and energy monitoring.

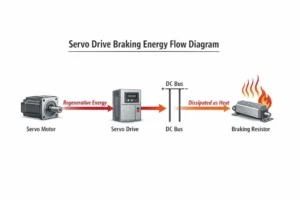

Application Example: Shunt Resistor in a VFD Braking Unit

During deceleration, the motor acts as a generator. The braking energy flows into the DC bus, raising voltage. A braking chopper circuit triggers the braking resistor, allowing current to flow through the VFD braking current shunt, which measures the actual current and prevents overvoltage by dissipating energy.

Conclusion: Matching Your Shunt Resistor to Application Demands

Selecting the right shunt resistor for a VFD system is not just about resistance values. It involves understanding power dissipation, durability, accuracy, and thermal performance. Always consult your VFD specification and braking cycle requirements before finalizing a current sense resistor.

Need help choosing the right model? Contact us to get personalized recommendations based on your braking unit design and application.