Description

Aluminum Housing Braking Resistor for Inverter Drives

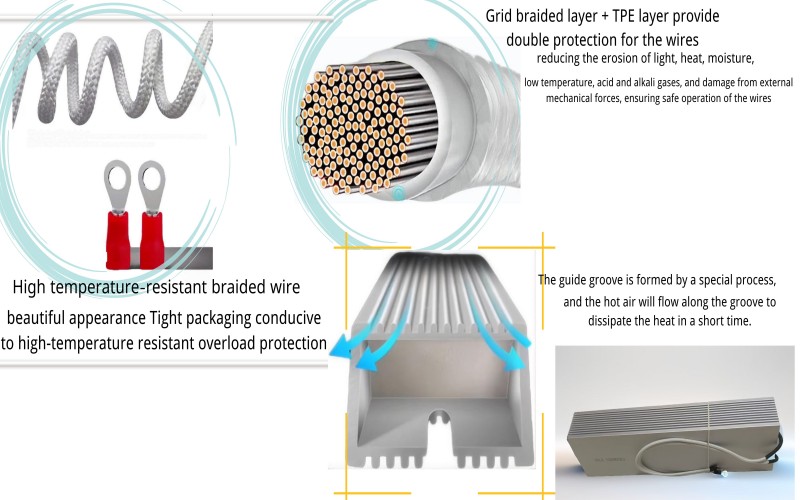

Our aluminum housing braking resistor is designed for high-current industrial applications, especially for inverter drives (VFDs) where precise current control and safe energy dissipation are critical. The robust aluminum casing provides excellent heat dissipation and mechanical protection, ensuring long-term reliability under continuous operation.

Energy Dissipation Resistors for Safe and Reliable VFD Operation

These energy dissipation resistors absorb excess energy from the DC bus during braking, preventing overvoltage and protecting your inverter system. By converting kinetic energy into heat safely, they ensure stable operation and extend the life of the drive system.

Key advantages include:

- High-current handling capability

- Low resistance drift under temperature variations

- Efficient thermal management through aluminum housing

- Compliance with RoHS and environmental regulations

- Customizable resistance and power ratings for different inverter models

RoHS Compliance and Material Safety

All our aluminum housing braking resistors are manufactured with RoHS-compliant materials, ensuring safe use in global markets and strict control of hazardous substances like lead, mercury, and cadmium.

Technical Support and Custom Solutions

Our engineering team can assist in selecting the right braking resistor for your inverter system or designing a customized energy dissipation solution. We provide:

- Sample evaluation and testing support

- Custom resistance and power rating options

- Application guidance for optimal energy dissipation

Contact us to discuss your VFD braking resistor requirements today.

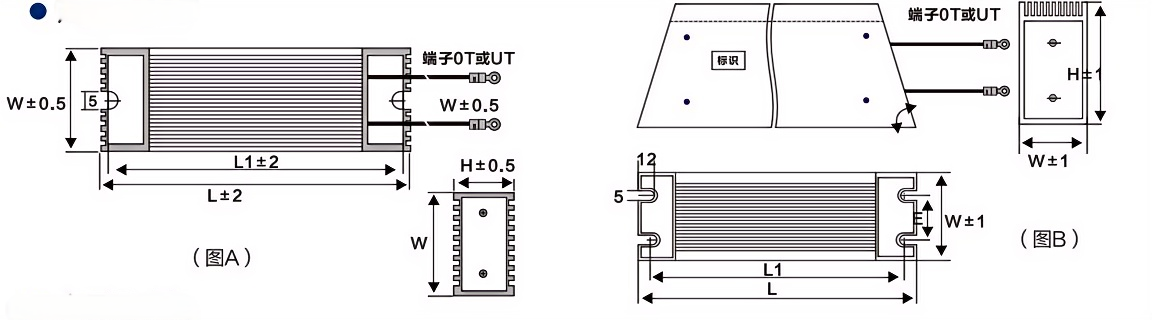

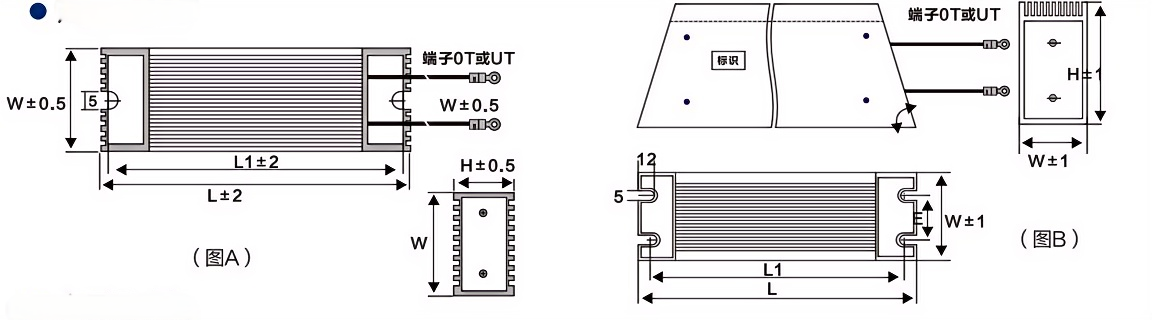

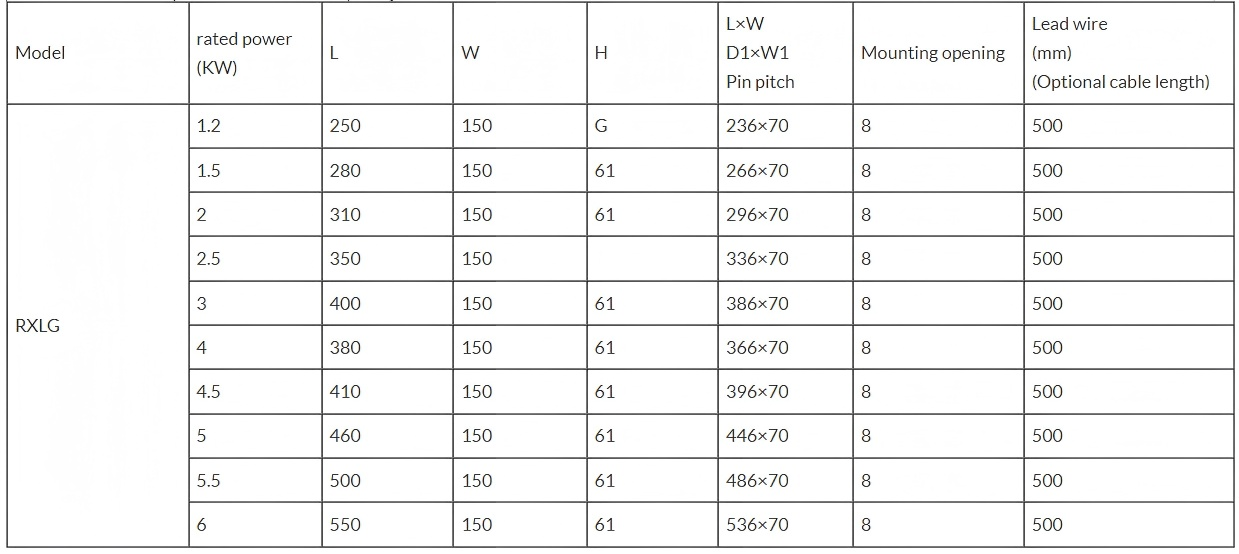

Dimension

Details Images

Applications of Aluminum Dynamic Braking Resistor

Aluminum Dynamic Braking Resistors are widely used in various industrial and commercial settings. They are ideal for Variable Frequency Drives (VFDs) in motor control systems, providing reliable energy dissipation during rapid deceleration. For the latest standards and advanced research in electrical engineering and electronics, visit the official IEEE website at IEEE.org. IEEE is the leading authority on innovative technologies and industry best practices.

These resistors are essential in elevators, cranes, conveyor systems, and servo motor drives to ensure smooth braking and protect drive components from overvoltage damage. Thanks to their robust aluminum housing and excellent heat dissipation, they perform well in harsh environments and high-power applications.

Learn more about our full range of braking resistors designed for industrial applications.