Description

M-Type Open-Air Metal Alloy Low-Value Resistor

The M-Type Open-Air Metal Alloy Low-Value Resistor (Ni-Cr Alloy) is specifically engineered for high-current and power dissipation applications where stable resistance and efficient heat dissipation are critical.

This open-air low-value resistor features an open-air structure that enables natural convection cooling, while the Ni-Cr alloy resistive element provides excellent thermal stability and long-term reliability.

As a robust open-air low-value resistor, it is well suited for demanding industrial power applications requiring consistent performance.

Key Features of Low value resistor

Open-air structure for efficient heat dissipation

Ni-Cr metal alloy resistive element

Low resistance values for high-current applications

M-type structure for mechanical strength and stability

Stable performance under thermal and electrical stress

Custom resistance values and power ratings available

Technical Parameters

| Parameter | Value |

|---|---|

| Power Range | 50W – 6KW (customizable) |

| Resistance Range | 10Ω – 300Ω |

| Tolerance | ±5% |

| Insulation Voltage | Up to 2.5kV |

| Housing Material | Aluminum alloy |

| Operating Temp | -55°C ~ +155°C |

| Mounting | Panel mount / Bracket |

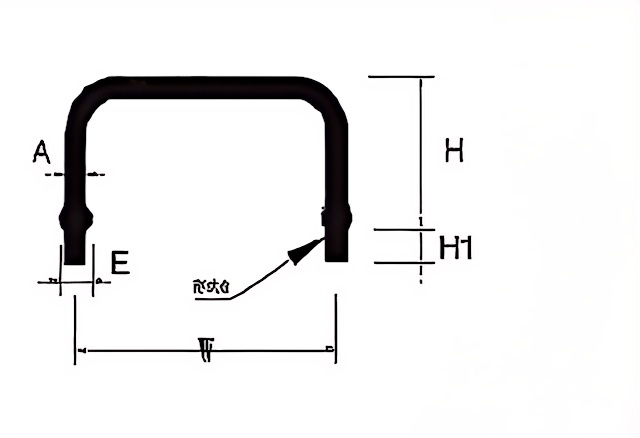

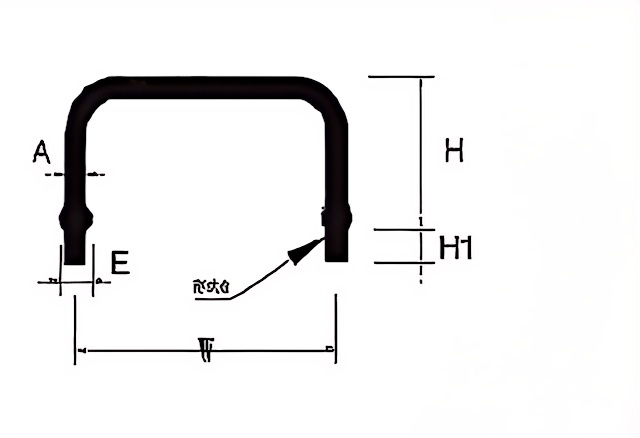

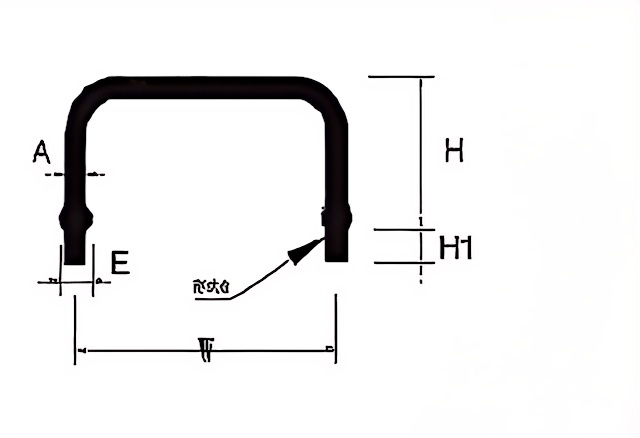

Product Nominal of Low value resistor

Material & Shape

| Material | Wire | Pin Pitch | Resistance | Shape |

|---|---|---|---|---|

| Current Shunt | K: K:Constantan (Copper-Nickel Alloy) M:Manganin (Copper-Manganese-Nickel Alloy) DX:Tin-Plated Copper NT:Copper-Nickel Alloy NG:Nickel-Chromium Alloy MN:6J16 Alloy(Manganin 6J16) MM:6J06 Alloy(Manganin 6J06) Nickel–chromium alloys are widely used in resistive components due to their thermal stability and oxidation resistance (see Nickel–Chromium Alloy ) | 10: 1.0mm | 10: 10mm / 20: 20mΩ | U: U type |

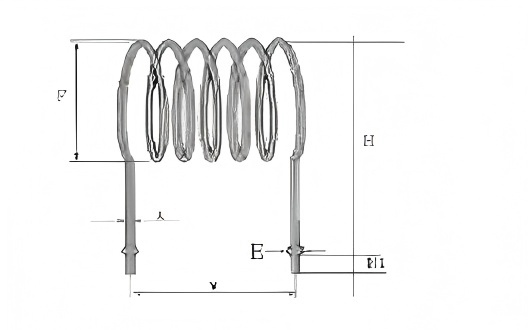

|  | (Orders are available) 1:Wire diameter of”A” 2:Rated current 3:Pin pitch Span of“W” 4:Resistance 5:Other requirements( height,pin pitch length,etc.) |  | M: M type, M2: M2 type, LX: Spiral, UZ: Folding feet, HX: HX |

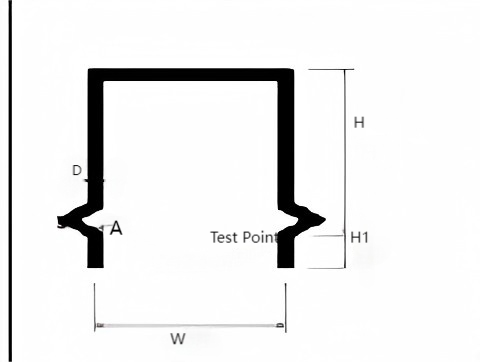

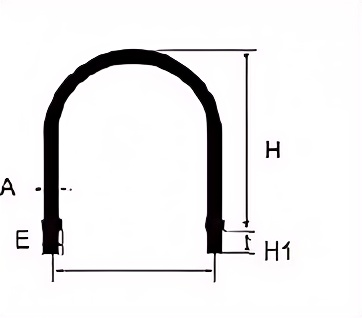

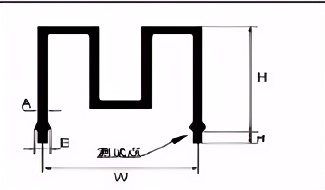

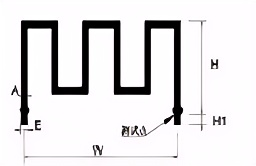

Product Shapes

| Product Shape | Product Shape | Product Shape |

|---|---|---|

U Type | UZ Type

| HX Type

|

M Type | M2 Type | LX Type |

Test Conditions

| Test Conditions | Max Resistance Change (ΔR%) |

|---|---|

| 1000 hours at 25°C (Loading Life) | ≤ 1% |

| 100 hours in Moisture | ≤ 1% |

| 1000 Thermal Cycles (-40°C to +150°C) | ≤ 1% |

Customization & Manufacturing

We offer customization based on your application requirements, including resistance value, power rating, terminal structure, and lead configuration.

Engineering support is available to help match the resistor to your specific working conditions.

FAQ

Q: What is the advantage of an open-air low-value resistor?

A: Open-air resistors dissipate heat more efficiently and maintain stable resistance under high current.

Q: Can resistance and power rating be customized?

A: Yes, both resistance and power rating can be customized.

Applications

EMS-assembled high-current power boards

Motor control modules and industrial drives

Inverter systems for renewable energy or automation

DC-DC converters and UPS systems

Battery management and EV controller circuits

- EMS manufacturers often rely on precision shunt resistors for real-time current monitoring.

In high-current battery packs, precision shunt resistors offer consistent performance over extended cycles.

Explore more current sensing resistors-Precision Metal Strip Shunt Resistor for DC-DC Power Modules