Description

Overview

This wire wound resistor is ideal for motor braking, power load testing, and industrial energy dissipation. With its robust aluminum housing and precise resistance tolerance, the wire wound resistor ensures stable and safe operation in AC/DC systems.

Key Features of Wire wound resistor

| Icon | Feature | Description |

|---|---|---|

| 🔥 | High Heat Dissipation | Aluminum alloy casing with excellent ventilation |

| ⚡ | High Voltage Tolerance | Withstands up to 2.5kV insulation for safe operation |

| 🛠 | Customizable | Power rating, resistance, and terminals available on request |

| 🌡 | Wide Temperature Range | Operates from -55°C to +155°C |

| 🧱 | Compact Design | Space-saving, easy to install in control panels |

Technical Specifications for wire wound resistor

| Parameter | Value |

|---|---|

| Power Range | 50W – 6KW (customizable) |

| Resistance Range | 10Ω – 300Ω |

| Tolerance | ±5% |

| Insulation Voltage | Up to 2.5kV |

| Housing Material | Aluminum alloy |

| Operating Temp | -55°C ~ +155°C |

| Mounting | Panel mount / Bracket |

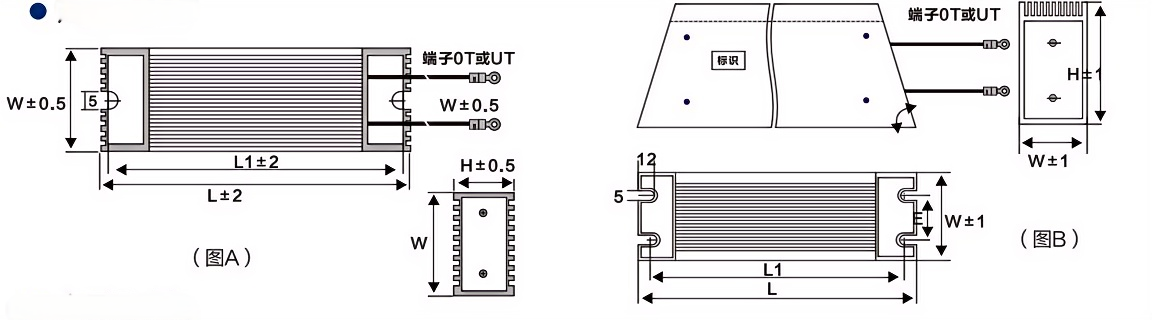

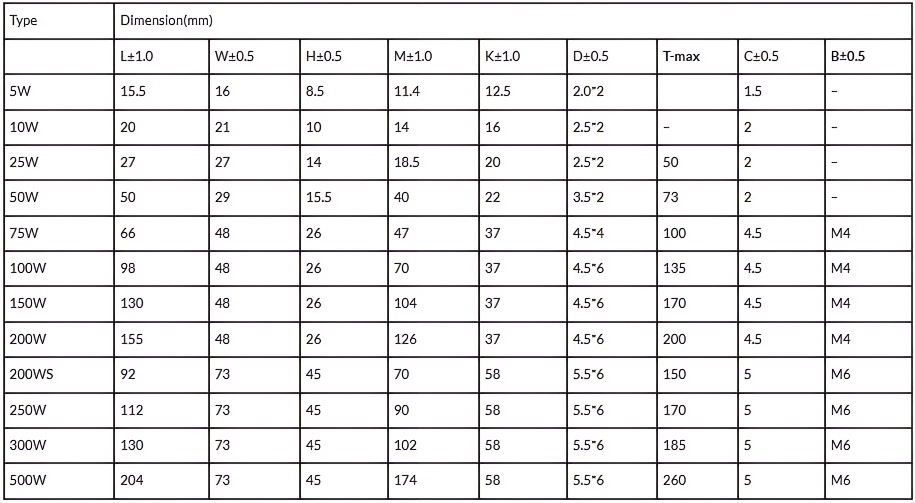

Dimension

VFD Power vs. Braking Resistor Power Selection Table (General Reference)

| VFD Power (kW) | Recommended Resistor Power (W) | Recommended Resistance (Ω) | Notes |

|---|---|---|---|

| 0.75 kW | 100–200 W | 100–150 Ω | Light-duty, fans |

| 1.5 kW | 200–400 W | 75–100 Ω | – |

| 2.2 kW | 300–600 W | 60–80 Ω | Standard braking |

| 3.7 kW | 600–800 W | 40–60 Ω | – |

| 5.5 kW | 800–1000 W | 30–50 Ω | Common industrial use |

| 7.5 kW | 1.0–1.5 kW | 20–40 Ω | – |

| 11 kW | 1.5–2.0 kW | 15–25 Ω | – |

| 15 kW | 2.0–3.0 kW | 10–20 Ω | – |

| 18.5 kW | 3.0–4.0 kW | 8–15 Ω | Heavy-duty applications |

| 22–30 kW | 4.0–6.0 kW | 6–10 Ω | Large equipment |

| 37–45 kW | 6.0–8.0 kW | 4–8 Ω | Cranes, hoists |

| ≥55 kW | ≥10 kW | 2–5 Ω | May use multiple resistors in parallel |

Applications of 100W Wire Wound Resistor

Our 100W wire wound resistor is ideal for motor braking and energy dissipation in AC/DC systems.

It ensures heat stability and long-lasting durability in power electronics.

Learn more about how these resistors work on

Electronics Tutorials.

Learn more about resistor applications in power systems.

Looking for smaller power models? Check out our Metal clad Chassis Mount Dynamic Braking Resistor